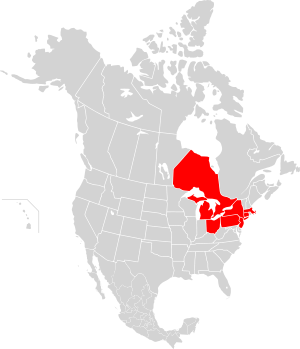

August 2003 — New York Blackout¶

- You were probably 5 or 6?

- I was halfway through grad school

It started here in Ohio

- Very hot. ⇨ high voltage lines sag, touches a tree ⇨ Ground Fault. ★ computer alarm fails ★ other locations ⇨ Load shedding begins.

- 4:40 ⇨ Power out in the major metropolitan areas in the red parts of the map.

- 1-5 days until power back. ~ 55 million people. $6 billion.

2006 — I graduate and join Gas Technology Institute (GTI)¶

The need for workable energy options is perhaps the greatest single challenge facing our nation and the world in the 21st century.

– MIT Energy Research Council, July 2006

- Funding from Government | Industry | member companies

- Near Chicago, with about 150-200 employees

- Expertise in the entire natural gas value chain

Quick technical review

The combustion triangle

Necessary for combustion:

- Fuel (the energy input; BTU/h)

- Heat (nitrogen/air - where and how much)*

- Oxidizer (air/O2 - where and how much)

Oxidizer

Fuel

Heat

* not for efficiency — a lower flame temperature reduces $NO_x$ (acid rain) pollution

Combustion chemistry requires a 10:1 air to fuel ratio

¶

$$CH_4 + 2 O_2 \rightarrow CO_2 + 2 H_2O $$$$PV = nRT \Rightarrow \text{volume} \sim \text{moles}$$$$\text{air} \approx 78\% N_2 + 21 \% O_2 + Ar\text{, etc.}$$... so ...

Combustion principles for burner development¶

- The maximum temperature is limited by the chemistry (about 3500 F for air-gas combustion).

- We can vary the amount and location of fuel or oxidizer to control temperature.

Oxygen-fired burners

¶

If Wikipedia is right, this idea is just a little older than you all (since the 1990s).

| Costs | Benefits | Practical for: |

|---|---|---|

|

|

|

Prior to oxy-fuel burners, gas-fired glass melting used complex heat recovery to preheat the air.

Otherwise there's no way to achieve the necessary temperatures. Of course, other fuels also worked.

Heat transfer — how to get heat to the load¶

- Radiation (like the bottom left burner); radiation ⇨ the sun

- Conduction (through solids, more for electric heat); conduction ⇨ pancake griddle

- Convection (like the bottom right burner); convection ⇨ boiling an egg

Thermodynamic principles for burner development¶

- Recapture heat from combustion:

- Increase the residence time of the hot gases.

- Use exhaust to heat things, as much as possible.

- Direct flame impingement, where practical.

- The temperatures we want are often nowhere near the flame temperature.

- Furnace designers would choose the furnace shape and burner position for best heat transfer.

Quick survey of burners

All shapes and sizes — for cooking, chemistry, melting, boiling ...¶

|

|

|

|

|

|

|

|

|  |

|

One of GTI's test furnaces¶

source: John Wagner's report on oscillting combustion (PDF) for the Department of Energy

Wok burner — in development ~ 2007 — gas prices still high

¶

Wok burner¶

From US Patent 7926479

Wok burner — performance¶

The new design more than doubles the best efficiency of existing burners — this uses half the fuel.

Caveat: with cheap gas, the speed-to-boil of the crazy nozzle ones may be more attractive (showmanship?).

Principles used¶

- Longer residence time ⇒ don't blow flame up the hood.

- All heat transfer is radiative ⇒ that's fine! We're cooking orange chicken, not melting steel.

2008-2011: An updated glass melter

Glass melter¶

- burners fire over a pool of molten glass

- lifespan about 20 years; afterward left with a lake of solid glass

Submerged glass melter¶

Burners fire from below, so

- It's possible to empty the furnace (and do smaller batches)

- There's more conductive

heat transfer - The flame loses a lot of temperature early; less NOx

- ⇨ up to 23% energy savings

(5-7% in an oxy-fuel melter);

more in air-fuel melter

up to 50% reduction in NOx

Source for efficiency data

Lawrence Berkeley National Lab glass energy guide

Principles used¶

- Lower flame temperature ⇒ less NOx

- Conductive + radiative heat transfer ⇒ more efficient than just radiative heat transfer

Boiler heat recovery¶

In 2008 the boiler team won a Chicago Innovation award

for a boiler heat recovery invention.

They combined it with other state-of-the-art boiler technology to make a "Super Boiler" with Cleaver Brooks.

- LPE — Low pressure exhaust

- HAH — Humidifying air heater

- HPE — High pressure exhaust

- TMC — Transport membrane condenser

(their invention)

Images are from a super boiler presentation to the DOE (PDF)

The same boiler — diagrammed¶

Inside the boiler design¶

Cutaway design¶

Data from Rick Knight's talk at the University of Texas

Principles used to get mid-90% boiler efficiency¶

- Recirculation increases flame residence time (super boiler) ⇒ more efficient

- Staged combustion reduces the initial flame temperature and allows a second burn in another chamber in the boiler

- Fins in the fire tubes give more surface area for conductive heat transfer

- Heat recovery using the condensed steam to preheat the incoming air

- And capture water from the flue gas using osmosis through porous membranes, rather than by precipitating it out with water ⇒ more efficient

Solar supplemented water heating¶

California Energy Commission report on solar heating for food processors

Principles used¶

- Preheat using the sun ⇒ use less fuel

End here unless there's extra time.¶

Any questions?

2007 — A thousand barrels a second

¶

- We moved from wood to coal thanks to the British Navy. Same for oil. And even nukes. A similar push to another energy source will be needed...

- We're running out — look at the prices. Conservation is necessary.

- Of course, the wors thing that could possibly happen for energy efficiency is a giant global financial crisis, because we (a) will stop caring about the environment and (b) will see consumption artificially decrease for a time and not be worried anymore.

Gas prices¶

The peak of all of this research was around 2004-2008, when natural gas was the most costly it's ever been. Research funding is lot more scarce now.

- 11 USD, sometimes 12 USD / MMBTU at the peaks

- We were running out of gas and looking to import it from Australia and Africa

- Now (2016; thanks to the commercialization of fracking and the bad global economy)

it's $2.30 / MMBTU

Vinod Khosla (Venture Capitalist) speaks at Stanford¶

- No time to play it now, but if you care the link's here for when you have time.

- Best quote: We don't want Louis Vuitton solutions, we want Walmart solutions.

- Basically, if everyone can't afford it, (like the Tesla cars) it's not a great idea

- He then advocates for painting roofs white, as a bigger contribution-per-dollar to energy efficiency than most other things people are doing.

- For me, electrifying. Reminds me of my HVAC professor (taught me welding at the local community college) who said the best thing we could do was "buy sunshades for the windows".

https://www.gsb.stanford.edu/insights/vinod-khosla-green-tech-must-first-make-economic-sense

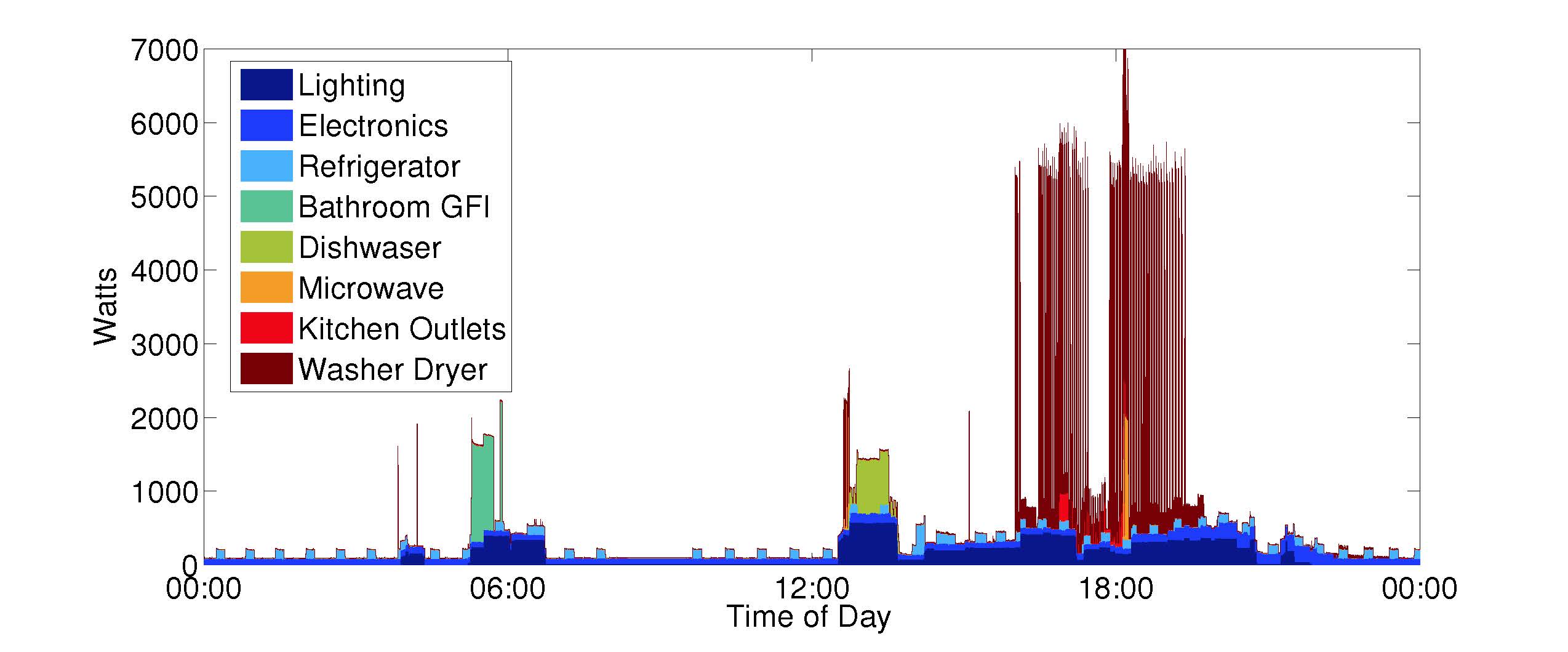

Agentis Energy — my new job¶

We used load disaggregation to identify discrepancies between businesses (like, an office leaving their A/C on all night long) and message them suggestions, like to put the A/C on a timer. This is paid for by utilities in states where they're required to have energy efficiency programs.

This image is from MIT because I couldn't find one from where I worked

McDonald's¶

Maybe surprising (or not since they have so many locations) — McDonald's has a big sustainability initiative including energy efficiency. Some ideas include

- $CO_2$ monitors indoors (to turn down the volume changes on the supplementary air intake when people aren't in the restaurant)

- Using hot water from the A/C to preheat the water going into the water heater.

- And standard stuff like buying $CO_2$ offsets and solar panels...

The McDonalds feature 'best of green'

A DOE presentation listing more technologies (PDF)

And even more (PDF)

What my first colleague was doing while I was in grad school

Oscillating combustion¶

Reduces $NO_x$ by lowering the flame temperature: pulse the flame by using an "oscillating" valve.

From US Patent 20060177785 A1, 2006

Small change¶

Put a valve in the fuel line and run it to pulse the fuel. This pulses the heat input, and lowers the maximum flame temperature.

John Wagner's report on oscillating combustor performance (PDF)

Here it is again – the valve is "Oscillator" on the fuel line¶

Shot of one of the three field test sites

¶

More on the annealing process for steel coils

Significant (numbers proprietary) reduction in NOx

¶

John Wagner's full report on oscillating combustor performance (PDF)

Principles used¶

- Lower flame temperature ⇒ less NOx

- Less fuel concentrated in one place ⇒ lower temperature

- Broader distribution of flame ⇒ more heat transfer by radiation